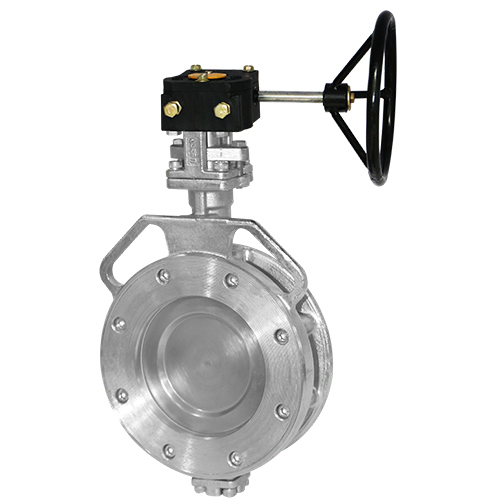

BUTTERFLY VALVE

BUTTERFLY VALVE Specification

- Connection

- Flanged

- Valve Type

- Butterfly Valve

- Material

- ], [

- Power Source

- Manual

- Pressure

- Medium Pressure

- Media

- Water, Oil, Gas

- Working Temperature

- Normal Temperature

- Port Size

- 2 inch

- Shape

- Round

- Standard

- IS/ANSI/DIN

- Operation

- Lever Operated

- Disc Material

- Stainless Steel

- Application

- Pipeline Flow Control

- Coating

- Epoxy Paint

- Seat Material

- Rubber

- Body Material

- Cast Iron

- End Connection

- Wafer Type

- Size Range

- 2 inch to 14 inch

- Color

- Blue

BUTTERFLY VALVE Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- 2 WAY

- Supply Ability

- 10 Pieces Per Day

- Delivery Time

- 1 Days

- Sample Available

- No

- Packaging Details

- AS PER CLIENT

- Main Domestic Market

- [, ', A, l, ', l, , n, a, ], I, d, i

- Certifications

- ISO

About BUTTERFLY VALVE

We, JOGANI are a leading manufacturer and Exporters of BUTTERFLY VALVE. This valve is easy and fast to open. A 90 rotation of the handle provides a complete closure or opening of the valve. Butterfly valves are used for on-off or modulating services and are popular due to their light weight, small installation footprint, lower costs, quick operation and availability in very large sizes. These valves can be operated by Handle, Gear, Pneumatic and Electrical Actuators.

Butterfly valves can be used for a broad range of applications within water supply, wastewater treatment, fire protection and gas supply, in the chemical and oil industries, in fuel handling systems, power generation etc.

Durable Construction and Superior Functionality

Built with a cast iron body, stainless steel disc, and rubber seat, this butterfly valve offers exceptional durability and corrosion resistance. The epoxy paint coating further extends its lifespan, making it a dependable choice for pipeline flow control in various environments. The lever operation allows for precise manual control over media flow.

Versatile Applications Across Industries

Designed to manage flow of water, oil, and gas at medium pressure and standard temperatures, this valve is ideal for municipal, industrial, and process pipelines. Its compatibility with IS, ANSI, and DIN standards ensures flexible integration into existing systems, while its round, flanged shape facilitates easy connection to pipes.

FAQs of BUTTERFLY VALVE:

Q: How is the lever operated butterfly valve installed in a pipeline?

A: This butterfly valve is installed using its wafer-type end connection, which sits between two pipe flanges. The flanged port size ensures secure mounting. Proper alignment and bolting are required to achieve reliable sealing and optimal performance.Q: What are the advantages of using a rubber seat with a stainless steel disc?

A: The combination of a rubber seat and stainless steel disc provides lasting durability, chemical resistance, and tight shut-off. This pairing minimizes leakage and wear, making the valve suitable for frequent operation in water, oil, and gas pipelines.Q: When should a manual lever operated butterfly valve be used?

A: Manual lever operated butterfly valves are optimal for applications where flow control does not require automation. They are suitable for routine maintenance, operational flexibility, and cost-effective solutions in medium pressure environments.Q: Where can this butterfly valve be sourced from in India?

A: This valve is available directly from authorized manufacturers and suppliers across India. It can be sourced for industrial, municipal, and commercial pipeline projects through distributors adhering to IS, ANSI, and DIN standards.Q: What is the typical process for operating the butterfly valve?

A: To operate the valve, simply move the lever to rotate the stainless steel disc inside. This opens or closes the flow path, allowing you to regulate the amount of media passing through the pipeline efficiently.Q: What benefit does the epoxy paint coating provide?

A: The epoxy paint coating offers enhanced protection against corrosion, wear, and harsh environmental conditions. It prolongs the life of the valve and ensures a consistent, reliable performance when installed in demanding operational settings.

Price 1200.0 INR/ Unit

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10 Pieces Per Day

- Delivery Time

- 1 Days

- Main Domestic Market

- [, ', A, l, ', l, , n, a, ], I, d, i

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Butterfly Valve Category

Offset Disc Design Butterfly Valve

Minimum Order Quantity : 10 Units

Material : Stainless Steel

Size : 3 Inch

Usage : Industrial

Power Source : Manual

Valve Type : Wafer Type Butterfly Valve

Damper Butterfly Valve

Minimum Order Quantity : 10 Units

Material : Stainless Steel

Size : 4 Inch

Usage : Industrial

Power Source : Electrical

Center Disc Design Butterfly Valve

Minimum Order Quantity : 10 Units

Material : Stainless Steel

Size : 10 Inch

Usage : Industrial

Power Source : Pneumatic

Valve Type : Wafer Type Butterfly Valve

Send Inquiry

Send Inquiry Send SMS

Send SMS